Scan the QR code add friend

Hotline

Phone

Service Email

Scan the QR code add friend

Hotline

Phone

Service Email

Industries Application

Aerospace and high-end transportation

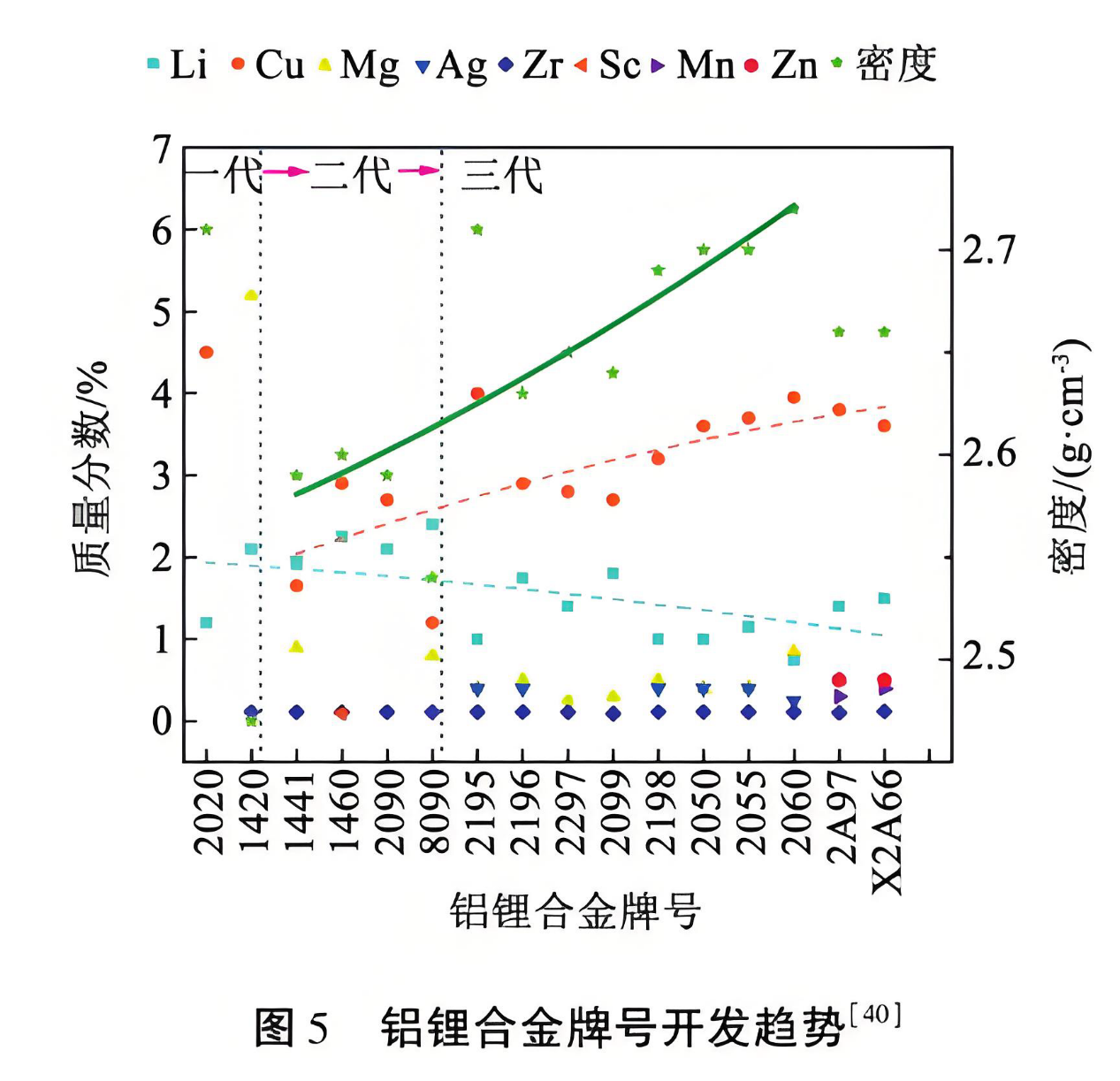

2014, 2017, 2024-T3, 7075-T6, 7178-T6 aluminum alloys have high static strength and are the main materials for the primary stage of the aviation industry.

2014-T6 aluminum alloy has high strength and excellent heat resistance, with a tensile strength of 470-510MPa, a yield strength of ≥ 415MPa, a Brinell hardness of about 150-160HB, and mechanical properties similar to some structural steels. It is commonly used to manufacture forged parts such as brake wheel hubs for military and civilian aircraft.

2014A-T6511 aluminum alloy is an improved version of 2014 alloy, with high strength and excellent fatigue performance. It can withstand repeated stress and cyclic loads well, and is suitable for manufacturing components such as aircraft wings and landing gear that need to withstand takeoff and landing cyclic loads, as well as key structural components such as fuselage frames and large load-bearing connectors, to ensure structural safety during flight.

2007-T4 aluminum alloy, with a tensile strength of up to 380MPa and a yield strength of 240MPa, has high strength and can withstand large pressure and impact loads. It is commonly used in the manufacturing of aircraft components, such as wing structural components, landing gear components, etc., which helps improve aircraft performance and fuel efficiency.

2011-T8 aluminum alloy has higher strength and hardness, and better wear resistance than most ordinary aluminum alloys. Its strength retention rate is ≥ 85% in an environment of 150-200 ℃, and its high-temperature stability is outstanding. It can be used for non core structural components such as aircraft frames and brackets that withstand high stress, and can cope with complex loads during flight.

2219-T6 aluminum alloy, after solid solution treatment at 535-545 ℃ and artificial aging at 165-175 ℃, has a tensile strength of 440-490MPa and a yield strength of 345-390MPa. It also has certain toughness and is not easily brittle when impacted. Die forgings and hand forgings that can be used in the aerospace field, such as core structural components such as aircraft wing beams and fuselage load-bearing frames, can withstand complex aerodynamic loads and takeoff and landing impacts during flight.

4032 aluminum alloy can work stably in an environment of 250-300 ℃ for a long time. At high temperatures, its mechanical properties decay slowly, and it is not easy to creep and relax. It is suitable for manufacturing small structural components that can withstand long-term high-temperature loads in aviation equipment, such as auxiliary high-temperature parts on aircraft. With its high strength and heat resistance, it ensures the stable operation of relevant components during flight, and its lightweight characteristics also meet the material weight reduction requirements in the aviation industry.

7075-T73 and 7075-T76 aluminum alloy materials have good stress corrosion resistance.

7175-T73 aluminum alloy, with ultra-high strength and top-notch load-bearing capacity, can be used as core load-bearing components for aircraft landing gear, wing main beam, fuselage frame, etc. It can withstand takeoff and landing impacts and complex aerodynamic loads.

7A04-T6 aluminum alloy, with ultra-high strength and excellent specific strength, can be used to manufacture key load-bearing components such as aircraft wing main beams, fuselage beams, landing gear, as well as structural frames for spacecraft, suitable for harsh conditions such as high altitude, low temperature, and takeoff and landing impact.

7475 T73/T76, It has a strength and stress corrosion resistance similar to 7075, with an increase in fracture toughness of over 30% and a significant improvement in fatigue performance.

Improved alloys such as 2214, 2218/2618, 2219/2319/2419/2519 have good heat resistance, and some alloys have good processing performance and are easy to weld. They are mainly used to manufacture heat-resistant weldable structural components and forgings.

7050/7150-T74 aluminum alloy has a strength increase of about 10% compared to 7475-T74 alloy, while maintaining the same level of KIC value, fatigue performance, and corrosion resistance.

The strength of 7055-T77 alloy is nearly 10% higher than that of 7050/7150 alloy in the same state, and the corrosion resistance is basically the same, but the KIC value is relatively low and the quenching sensitivity is poor.

The 2124/2224/2324/2024 aluminum alloy developed on the basis of 2024 aluminum alloy has further improved its comprehensive performance.

7449-T79/T74 aluminum alloy has a strength 10% to 20% higher than 7050-T76/T74 alloy, and its fracture toughness is basically equivalent. It has good resistance to peel corrosion, stress corrosion, and fatigue performance.

2524-T3、 Aluminum alloys such as 2624/2724/2824, 2026/2027/2028/2029 have better resistance to fatigue crack propagation.

The strength and fracture toughness of 7085-T7452 alloy forgings are about 12% and 15%~20% higher than those of 7050-T7452, respectively. They have better hardenability, higher damage tolerance, and superior fatigue crack propagation resistance.

7136-T76 alloy extruded profiles have the characteristics of ultra-high strength and high toughness, and are used in the manufacturing of upper wing skins, beams, and wing tails for Boeing 787, 747-400LCF, and Airbus A380;

7056-T7951 aluminum alloy has excellent fracture toughness, which is about 40% higher than 7449-T76/T74 aluminum alloy, and is used to prepare the upper wing panel of A380 aircraft.

The strength and toughness of 7042-T6 alloy forgings are 25% to 35% higher than those of 7075-T6/7050-T74 alloys of the same specification.

7040/7140-T76/T74 alloy has higher strength and KIC values compared to 7075-T76/T74 alloy, better processing performance, and significantly improved fatigue crack propagation resistance.

7037 aluminum alloy has better comprehensive performance than 7050 and 7010 aluminum alloys, and 7037-T7452 forgings have been used in Airbus A400M transport aircraft.

7099-T7651/T7451 aluminum alloy has a strength more than 15% higher than 7050-T7451 aluminum alloy, and has better fracture toughness and stress corrosion resistance, with excellent comprehensive performance.

The performance indicators of 7255-T7751 alloy comprehensively exceed those of 7449-T7951 aluminum alloy.

2000 series aluminum alloys containing Ag, such as 2039/2139, 2040, 2029, etc., have good heat resistance.

The 7042 aluminum alloy containing Sc is superior to the 7050-T74 aluminum alloy in terms of strength, fracture toughness, and stress corrosion resistance.

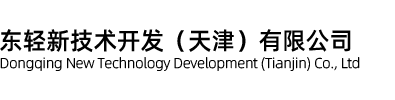

1420 aluminum lithium alloy has good weldability, high corrosion resistance, high elastic modulus, and sufficient strength. Compared with the Д 16 alloy, the density of 1420 aluminum lithium alloy is 12% lower and the elastic modulus is increased by 8%.

2090 and 8090 alloys with approximately 2% lithium addition are about 10% lighter and have higher hardness compared to traditional alloys.

1430 and 1441 aluminum lithium alloys have an elastic modulus and fracture toughness about 10% higher than that of Ø 16 aluminum alloy.

1440 aluminum lithium alloy has better ductility, with an elongation rate of 1.5~2 compared to 1430 and 1441 aluminum lithium alloys.

1450 and 1451 aluminum lithium alloys were developed based on the AI CuLi system, which exhibit high strength and corrosion resistance at high temperatures.

1460 aluminum lithium alloy developed by adding Zr and Sc for welding low-temperature fuel tanks.

High strength 1441 aluminum lithium alloy has better plasticity and can be used to prepare 0.25mm thick plates, mainly for internal components of aerospace control systems.

2195 aluminum lithium alloy has high strength, crack resistance, fatigue life resistance, and corrosion resistance, and is used to manufacture ultra lightweight external storage tanks for space shuttles and thrust panels for launch vehicle fuel tanks.

2198 aluminum lithium alloy is an improved version of 2195 aluminum lithium alloy, which has significant advantages in specific stiffness, tensile strength, fatigue life, and corrosion resistance.

2199 and 2060 aluminum lithium alloys are specifically developed for aircraft lower wing skin sheets.

2050 aluminum lithium alloy, with lower density of thick plates, high fatigue resistance, and lower quenching sensitivity, has been used in the lower wing structure of A380 to replace the wings, ribs, and other internal components of the fuselage made of 7050 aluminum alloy medium thick plates.

X2A66 aluminum lithium alloy is independently developed by China. This alloy has excellent characteristics such as high strength and toughness, fatigue resistance, corrosion resistance, good thermal stability, and good plasticity. Its ultimate tensile strength is above 510 MPa, elongation is greater than 8%, and KIC can reach 30 MPa · m1/2 or more. Therefore, this alloy is widely used in the manufacture of aircraft integral wall panel structures.

2055 aluminum lithium alloy, compared with 7075 T6511 aluminum alloy, has a 4% decrease in density, a 25% to 30% increase in tensile strength and yield strength, and an 8% increase in elastic modulus; Compared with 7150-T7511 aluminum alloy, the density is reduced by 5%, the fracture toughness is increased by 8%, and the elastic modulus is increased by 7%. 2055 aluminum lithium alloy has mechanical properties comparable to 7055 aluminum alloy, but with lower density, better elastic modulus, and corrosion resistance.

Tell us your aluminum material requirements

We will reply to your email within 2 working days

Submit